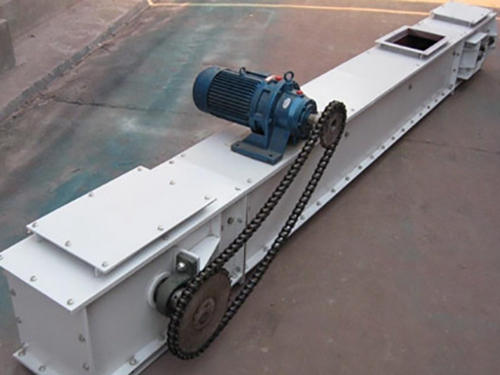

Buried scraper conveyor

The whole structure of the buried scraper conveyor is reasonable, and it can be fed at multiple points. The moving speed of the scraper is driven by the planetary cycloid pinwheel reducer, and the operation is stable and the noise is low. Buried scraper conveyor is a kind of material conveying system equipment which is very popular in metallurgy, mining and thermal power plants. Buried scraper conveyor is widely used in metallurgy, building materials, electric power, chemical industry, cement, port, wharf, coal, mine, grain and oil, food, feed, and other industries and departments.

Buried scraper conveyor is a conveyor that uses the friction between the moving chain scraper and coal to continuously output the coal chain scraper, which is embedded in the transported coal and fixed on the traction chain during operation, to transport the bulk materials in the closed material trough. The drag chain and scraper of the conveyor are embedded in the material, the scraper only accounts for a part of the cross-section of the chute, and the material accounts for most of the cross-section of the chute.

Buried scraper conveyor can transport materials horizontally, obliquely or vertically. In horizontal conveying, the scraper is a flat strip. Based on the principle that the cutting force of the chain embedded in the bulk material and the scraper to the bulk material layer is greater than the resistance of the groove wall to the bulk material, the bulk material moves forward together with the scraper. At this time, the ratio of the height of the moving material layer to the width of the groove is within the ratio range, and the material flow is stable.

When the scraper conveyor is conveying horizontally, the material is subject to the pressure of the scraper chain in the moving direction and the weight of the material itself, which produces internal friction between the materials. This kind of friction ensures the stable state between the material layers, and is enough to overcome the external friction caused by the movement of materials in the groove, so that the materials can form a continuous and integral material flow and be transported.

When the buried scraper conveyor is lifted vertically, the material is under the pressure of the scraper chain in the moving direction, which produces the lateral pressure in the transverse direction and forms the internal friction force of the material. At the same time, due to the continuous feeding of the water level section, the lower materials successively produce the pushing force on the upper materials. This kind of friction and pushing force is enough to overcome the external friction resistance caused by the movement of materials in the machine slot and the weight of the materials themselves, so that the materials form a continuous overall material flow and are lifted.

Selection principle of buried scraper conveyor:

The buried scraper conveyor is mainly composed of the shell (slot), scraper chain, driving device and tensioning device of the closed section. The equipment is simple in structure, small in volume, good in sealing performance and convenient in installation and maintenance; it can be used for multi-point feeding and multi-point unloading, and the process selection and layout are relatively flexible; it can improve working conditions and reduce environmental pollution when transporting flying, toxic, high temperature, flammable and explosive materials. The models include: general type, hot material type, soda ash special type (ordinary type, type), grain special type, cement special type, power plant special type, etc., with tank width of 120-1000mm.

The buried scraper conveyor has the following requirements for materials:

(1) Loose density of material: P = 0.2 ~ 2.5t/m3.

(2) Material temperature: the general model is applicable to the material temperature less than 120 ° C; the temperature of the hot material conveying material is 100 ~ 450 ° C, and the instantaneous material temperature is allowed to reach 800 ° C.

(3) Moisture content: the moisture content is related to the material's material quality and viscosity. Generally, it should be considered as the degree that the material can still be loose after being kneaded into a mass by hand.